Advance production facilities allow qualitative and cost-effective products. Keeping this in view, we have nurtured ourselves with high grade machines for product development. Also, we use premium raw materials and finishing products that gives our products durability and efficiency. We make sure that all our products dimensional accurate and in accordance as per customer’s requirement.

We are pleased to inform about our process of working. First we take drawing, we study the drawing and analysis the drawing then give a quotation to customers with products delivery time then take purchase order and send samples for approval process, after inspection report we will start the production.

We strongly believe in quality controls, each process of production carried out under supervision of quality control supervisors. We checked the products three times at every production stage. We have skilled professional team in all department and all this staff working under guidance of our Directors Mr. Tarun Vasoya & Mr. Jay Vasoya.

We Can Provide:

- We provide the below list of Documents as per customer’s requirement with Samples or Production Batches:

- Inspection reports and Material Test certificate with all deliveries (IMDS Data)

- Production Part Approval Process (PPAP) Documentation Samples with Initial Sample Submission Report.….

- Process Failure Mode Effects Analysis (PFEMA)….

- Material Tracking & Traceability Systems(IQMS)

- Statistical Process Control (SPC)

- REACH & ROHS Certified products.

- Surface Treatment Reports.

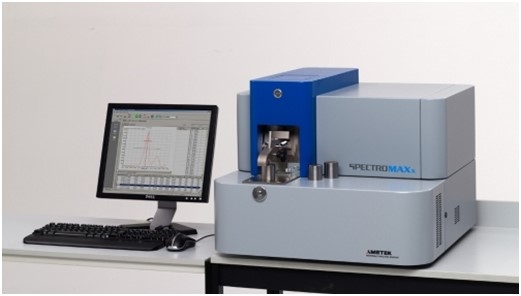

Metallurgical Lab:

Metallurgist lab is equipped with high precise measuring like Spectro, Portable hardness, Niton gun, Microscope, etc…

- Spectro for Chemical Composition Test.

- Portable XRF Analyzer for Grade Inspection.

- Jominy Set up for Jominy End Quench Test.

- AUTO Cutting & Polishing Machine for Batter Sample Preparation for Metallography.

- Microscope for Microstructure inspection.

- Measuring Microscope for Defect measurement.

- Portable Hardness Tester to check hardness on Heavy Weightage Parts.

- Millipore Testing for product cleanliness.

- Micro Vickers Hardness Tester for Case Depth Measurement.

- Digital Super Ficial Rock well hardness tester.

- Rock well hardness tester for HRC, HRA, HB Testing.

- Auto Brinnal Hardness Tester for BHN testing (up to 3000 KG Load)

- Ultrasonic Flow detector for defect inspection on RM & Product.

- Coating thickness.

Standard Room Facility (Precision Measuring Equipment)

Standard Room is equipped with highly precise measuring like CMM, Contour tester, Roundness tester, Profile projector, Equator, Multi dimension inspection gauge etc.